All rights reserved by ALF ENGINEERING Pvt Ltd

All, hydroformed components tare lasercut to create high quality weld joints, higher productivity, besides component accuracies. ALF has invested in top of the line machines from M/s Trumpf and M/s NTC for this purpose.

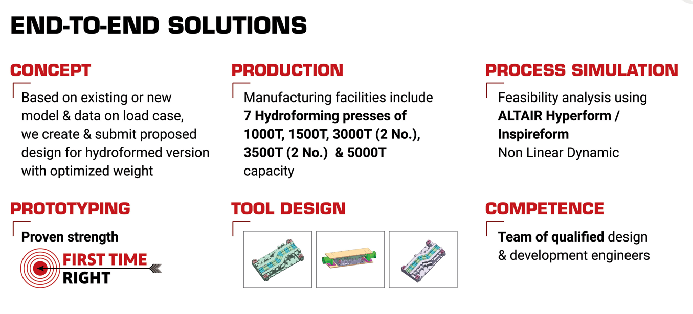

ALF offers a complete solution in hydroforming, from concept to production. We have proven this over many development cycles of products for different automotive manufacturers. ALF has a dedicated design center for this purpose in Nasik, and has currently 7 hydroforming presses from 1000T to 5000T from Schuler & Electro-Pneumatics.

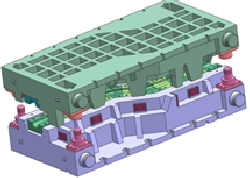

All tools are designed in-house, and manufactured in India from reputed toolrooms.

All tools are designed in-house, and manufactured in India from reputed toolrooms.

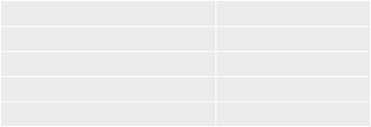

Type of construction

Vehicle

Tubular

SUV, Pickup

C-in-C

MPV, SUV, LCV

Hydroformed

SUV, LCV

‘C’ Channel

LCV

ALF has experience in Manufacturing all Chassis Designs

Concept : Based on existing model & data, ALF will submit proposed design for hydroformed version of components optimising weight and cost.

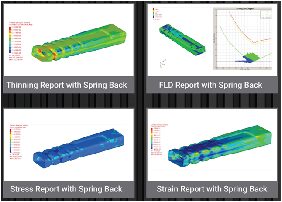

Process Simulation : Feasibility analysis using ALTAIR Hyperform., Forming Suite

Tool Design : Unigraphics NX4 & CATIA for design, Autocad

Prototyping : Proven strength –First Time Right – shortest time

Production : Team of qualified design & development engineers

Process Simulation : Feasibility analysis using ALTAIR Hyperform., Forming Suite

Tool Design : Unigraphics NX4 & CATIA for design, Autocad

Prototyping : Proven strength –First Time Right – shortest time

Production : Team of qualified design & development engineers