All rights reserved by ALF ENGINEERING Pvt Ltd

ALF has integrated facilities, with dedicated production lines for the manufacture of chassis’ for various vehicles. Besides, assembly lines are also installed for mass production of suspension and other assemblies.

ALF has attained a high level of competence and score in mass manufacturing approvals, and the continuous improvements acheived when developing the latest products, is horizontally deployed on the older lines as well.

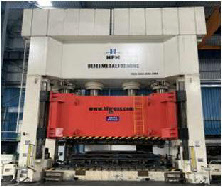

Besides conventional hydraulic and mechanical presses, ALF has also investmented in servo-mechanical presses, to benefit from improved productivity, besides lower levels of noise pollution.

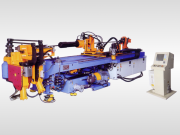

In the continous improvement cycle, ALF has re-invested in newer CNC bending machines, which offer much higher productivity and better component accuracies.

Robotic welding was first introduced 15 years ago, and has since been expanded. Now all assembly lines are robotized for maximum productivity and high quality welds.

In the quest for continuous improvement of productivity and product quality, ALF has first invested in 3D laser cutting machines, with the best in class machines from Trumpf., NTC Komatsu. Today we have over 12 such machines with resultant edge quality of parts.

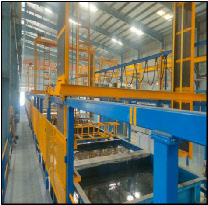

Initially, ALF had installed a number of Autophoretic painting lines, as a ‘green’ revolutionary process that delivers a high quality finish, and is less capital intensive, compared to E-coat solutions. In the constant push for more durable surface coating demands from our customers, a number of CED plant are also installed at Sricity, Hosur, Nasik, etc

ALF recognizes that inhouse Tooling competence for design and manufacture will benefit our customers. Accordingly, it has started the investments and manufacturing at a ToolShop in Nasik

ALF is also investing in Tandem Press Lines to improve productivity and value proposition to customers requiring BIW Parts.

All ALF plants are IATF Certified, as also for EMS and OHSAS.

ALF has attained a high level of competence and score in mass manufacturing approvals, and the continuous improvements acheived when developing the latest products, is horizontally deployed on the older lines as well.

Besides conventional hydraulic and mechanical presses, ALF has also investmented in servo-mechanical presses, to benefit from improved productivity, besides lower levels of noise pollution.

In the continous improvement cycle, ALF has re-invested in newer CNC bending machines, which offer much higher productivity and better component accuracies.

Robotic welding was first introduced 15 years ago, and has since been expanded. Now all assembly lines are robotized for maximum productivity and high quality welds.

In the quest for continuous improvement of productivity and product quality, ALF has first invested in 3D laser cutting machines, with the best in class machines from Trumpf., NTC Komatsu. Today we have over 12 such machines with resultant edge quality of parts.

Initially, ALF had installed a number of Autophoretic painting lines, as a ‘green’ revolutionary process that delivers a high quality finish, and is less capital intensive, compared to E-coat solutions. In the constant push for more durable surface coating demands from our customers, a number of CED plant are also installed at Sricity, Hosur, Nasik, etc

ALF recognizes that inhouse Tooling competence for design and manufacture will benefit our customers. Accordingly, it has started the investments and manufacturing at a ToolShop in Nasik

ALF is also investing in Tandem Press Lines to improve productivity and value proposition to customers requiring BIW Parts.

All ALF plants are IATF Certified, as also for EMS and OHSAS.