All rights reserved by ALF ENGINEERING Pvt Ltd

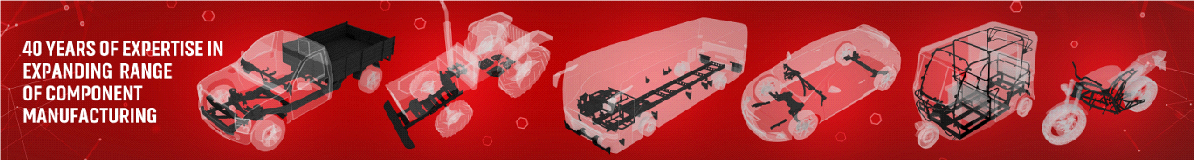

ALF Engineering Pvt Ltd is an auto ancillary, a company established in 1980 in suburban Mumbai.

Recognized as a leading, and much awarded, supplier to OE’s in India, its main business areas are in the Chassis Frame, Front & Rear Cradles, Suspension assemblies, Hydroformed components for SUV’s, MUV’s & LCV’s. It currently manufactures and supplies over 1700 frames/day from 14 facilities pan India to Mahindra & Mahindra, Ashok-Leyland, Tata Motors, Isuzu Motors , Stellantis and Daimler India.

It is further setting up 2 new Greenfield plants for new generation chassis.

ALF is also the leading supplier for design and development of hydroformed components, and has 7 hydroforming presses (1000-5000 Tons).

ALF’s latest venture is to manufacture Hotstamped parts, for which a state of the art facility has been set up in Khed City near Pune. The plant has equipment from the world’s leading companies in the PHS space, including AP&T, Benteler & ISGEC.

ALF has now set up a Product Engineering Division, and has full FSS capabilities to support customers in the area of chassis engineering, from part design > assembly > integration for all chassis parts and assemblies.

All plants have Certifications in IATF 16949, ISO 14001 and ISO 45001.

Currently its main business area is the chassis frame, suspension assemblies and hydroformed components for SUV’s, MUV’, LCV’s. It has recently added Hot Formed parts and assemblies to its range of products.

Since technology is at the centre of all development, ALF has a Design Centre at Nasik for supporting customers in the development of hydroformed components – concept – simulation – tooling development – prototyping. Subsequently production is ramped up, at a suitable plant location.

There are CED and Autophoretic paint shops for chassis at Nasik, Chakan, Sricity, Hosur offering the latest in cost effective painting technology.

Recognized as a leading, and much awarded, supplier to OE’s in India, its main business areas are in the Chassis Frame, Front & Rear Cradles, Suspension assemblies, Hydroformed components for SUV’s, MUV’s & LCV’s. It currently manufactures and supplies over 1700 frames/day from 14 facilities pan India to Mahindra & Mahindra, Ashok-Leyland, Tata Motors, Isuzu Motors , Stellantis and Daimler India.

It is further setting up 2 new Greenfield plants for new generation chassis.

ALF is also the leading supplier for design and development of hydroformed components, and has 7 hydroforming presses (1000-5000 Tons).

ALF’s latest venture is to manufacture Hotstamped parts, for which a state of the art facility has been set up in Khed City near Pune. The plant has equipment from the world’s leading companies in the PHS space, including AP&T, Benteler & ISGEC.

ALF has now set up a Product Engineering Division, and has full FSS capabilities to support customers in the area of chassis engineering, from part design > assembly > integration for all chassis parts and assemblies.

All plants have Certifications in IATF 16949, ISO 14001 and ISO 45001.

Currently its main business area is the chassis frame, suspension assemblies and hydroformed components for SUV’s, MUV’, LCV’s. It has recently added Hot Formed parts and assemblies to its range of products.

Since technology is at the centre of all development, ALF has a Design Centre at Nasik for supporting customers in the development of hydroformed components – concept – simulation – tooling development – prototyping. Subsequently production is ramped up, at a suitable plant location.

There are CED and Autophoretic paint shops for chassis at Nasik, Chakan, Sricity, Hosur offering the latest in cost effective painting technology.

Zaheerabad (P2)

Nasik ( P1 )

Chakan

All plants certified and linked

ALF has been annually evaluated for Sustainability by ECOVADIS

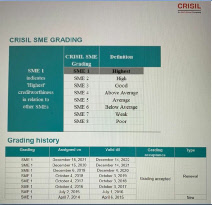

Financial Rating

Consistently Highest

year after year

Consistently Highest

year after year

Sustainability Rating

Khedcity

Sricity

Nasik Pl 4

Nasik P4

Open in Chrome